Rapid and Repeatable Fluorescent Speckle Pattern Fabrication Using a Handheld Inkjet Printer

Abstract

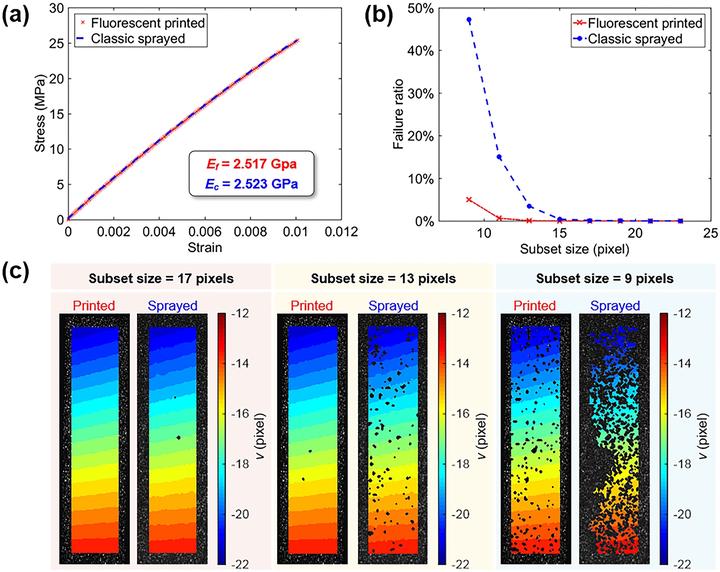

Background: compared with regular speckle patterns formed by reflecting the illumination light, fluorescent speckle patterns generated by the emitted light of fluorescent particles offer distinct advantages of specular reflection elimination, high speckle contrast, and multi-surface/scale deformation measurement. These advantages of fluorescent speckle patterns enhance the quality and applicability of digital image correlation measurements. Objective: to facilitate the implementation of fluorescent DIC, a designable, rapid and repeatable fluorescent speckle pattern fabrication method using a handheld inkjet printer is proposed. Method: with the aid of quick-drying fluorescent ink cartridge, the handheld inkjet printer is capable of printing numerically generated digital speckle patterns on test sample surfaces, which allows designable, rapid and repeatable fluorescent speckle pattern fabrication in few seconds. By illuminating the printed fluorescent digital speckle pattern with ultraviolet light, the emitted blue light forms a high-contrast speckle image on the camera sensor. Result: with the handheld inkjet printer used in this work, the smallest size of the printed dot (i.e., speckle granule) is estimated as ~ 78 μm and the fluorescent speckle pattern can be printed on both planar and curved surfaces of various materials. For validation, the performance of the proposed fluorescent speckle pattern fabrication method was compared with conventional speckle pattern fabrication methods via a uniaxial tensile test and a high-throughput tensile test. Conclusions: the results confirmed the better quality and measurement results of the printed fluorescent speckle patterns.